SPM HD

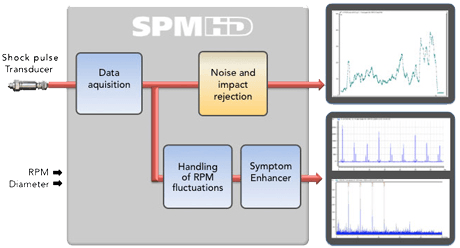

SPM HD is a patented further development of the Shock Pulse Method (SPM) used for fast, easy and reliable diagnosis of the operating condition of rolling element bearings.

Advanced digital technique and RPM-based sampling frequency makes SPM HD particularly well suited for measurement on low speed applications. Sophisticated mathematical algorithms makes the measuring technique less sensitive to interference from other signals. Extraordinary signal quality and 24 bit A/D conversion provides razor sharp resolution and exceptional detail in spectrums and time signals. Time signals are very easily interpreted, making the type and extent of the damage simple to determine. SPM HD can be used to monitor applications in the 0.1 - 20,000 RPM range.

Throughout their lifetime, bearings generate shocks int he interface between the loaded rolling element and the raceway. These shocks 'ring' the SPM transducer which outputs electric pulses proportional to the shock magnitude. Unlike vibration transducers, the shock pulse transducer responds at its carefully tuned resonance frequency of about 32 kHz, enabling a calibrated measurement of the shock pulse amplitudes.

Shock pulse amplitude is due to three basic factors:

- Rolling velocity (bearing size and rpm)

- Oil film thickness (separation between the metal surfaces in the rolling interface). The oil film depends on lubricant supply and also on alignment and pre-load.

- The mechanical state of the bearing surfaces (roughness, stress, damage, loose metal particle).

Input data

The effect of rolling velocity on the signal is neutralized by entering rpm and shaft diameter as input data with 'reasonable accuracy'. This sets an initial value (HDi), the start of the 'normalized' condition scale.

Output data

The SPM HD method produces four different types of results:

- HDm

- HDm is a scalar value expressed in decibels. It is the primary value to use to determine the severity of a bearing damage. It represents the highest shock pulses found during the measuring cycle. This value is also used for triggering alarms.

- HDc

- HDc is a scalar value expressed in decibels. This value represents the level where 200 shocks/second are present. It is useful to determine lubrication condition.

- Time Signal HD

- Time signal HD is extremely useful to locate where in the bearing a possible damage is located. In many cases it is also possible to determine the nature of the damage (cracked inner race with spalling all around or a single crack etc.). The Time signal HD is a result of very advanced digital algorithms where repetitive shocks are enhanced and random signals are suppressed.

- SPM Spectrum HD

- SPM Spectrum HD is the result of applying FFT algorithms on the Time Signal HD. The SPM HD spectrum is usefule to determine where a possible bearing damage is located. It is also useful for trending purposes (applying symptom and band values).

EvaluationThe initial value and the range of the three condition zones (green-yellow-red) was empirically established by testing bearings under variable operating conditions. The maximum value places the bearing into the condition zone. The height of the carpet value and delta (HDm minus HDc) indicated lubrication quality or problems with bearing installation and alignment.HD Order TrackingOn machinery operating under variable speed, analysis with High Definition Order Tracking provides reliable data and crystal clear measuring results even when RPM varies greatly during the course of measurement. Order Tracking is applicable in a very wide RPM range, from just a few thousands or revolutions per minute.