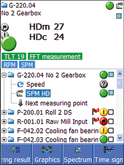

The Leonova Emerald is a straightforward and efficient portable instrument for condition measurement in rough industrial surroundings. It is the perfect wear and tear choice for powerful analysis and troubleshooting in machine condition monitoring. Leonova Emerald supports HD Technologies for bearing condition and advanced vibration analysis for general machine condition, and more features.

Leonova Emerald

Over 30 Years of Experience Licensed and Certified: ISO 18346-2 / Cert. 9407-0089B

Features:

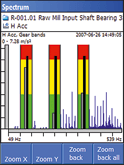

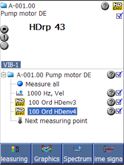

Leonova Emerald includes High Definition Shock Pulse Method (SPM HD) for bearing condition and advanced vibration analysis for general machine condition.

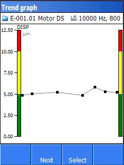

Bearing Condition

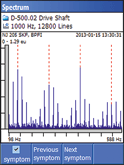

Vibration Analysis:

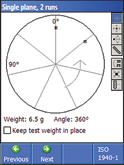

Corrective Maintenace:

Order Tracking:

Emerald Brochure

Call Us Today for More Information or to Place an Order!

800-997-4467