The RollProf 3T PM 1000 is a complete, high-precision roll profiling system designed for in-situ roll measurement in demanding industrial environments. Engineered in collaboration with maintenance experts from the paper and steel industries, the RollProf PM 1000 enables accurate, full-length roll profile measurement without removing the roll from the machine—making it ideal for shutdown inspections and condition-based maintenance programs.

Designed for rolls with diameters from 400 to 1000 mm, the PM 1000 requires only 45 mm of clearance above the roll, allowing measurements in tight spaces where traditional systems cannot operate. Its robust yet user-friendly design ensures fast setup and reliable operation, helping maintenance teams quickly assess roll condition and make informed decisions.

With an ultra-high resolution of 0.0001 mm, the RollProf PM 1000 delivers precise, repeatable results that support predictive maintenance strategies. By measuring actual roll condition rather than relying on fixed replacement intervals, users can extend roll life, reduce unnecessary replacements, minimize downtime, and significantly lower maintenance costs.

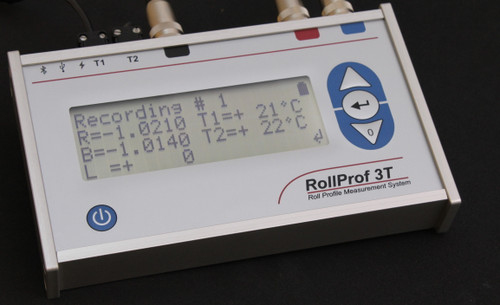

The complete system includes a Bluetooth data logger, two sensors, a pulse wheel, dedicated RollProf software, and two protective carrying cases, providing everything needed for accurate in-situ roll profiling straight out of the box.

Ideal for production environments where accuracy, efficiency, and reliability matter, the RollProf 3T PM 1000 is a proven solution for optimizing roll maintenance and improving overall operational performance.