The RollProf 3T 1000-1600-100P is a complete, high-precision roll profiling system designed for accurate in-situ and workshop measurement of industrial rolls. Engineered in collaboration with maintenance experts from the paper and steel industries, RollProf delivers exceptional accuracy, durability, and ease of use in demanding production environments.

This advanced roll profiler measures roll profiles and lengths with an ultra-fine resolution of 0.0001 mm, supporting roll diameters from 100 to 1600 mm. The system includes a complete RollProf PM 1000 in-situ measurement solution for roll diameters ranging from 400 to 1000 mm, making it ideal for both installed and removed rolls.

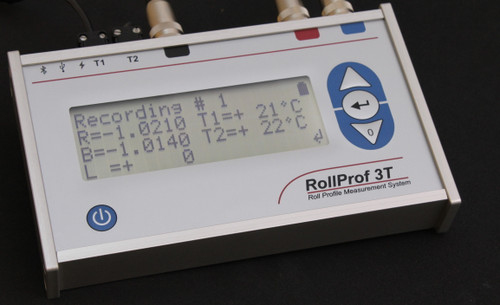

The RollProf 3T system is supplied as a turnkey package, including a Bluetooth data logger, precision sensors, dual pulse wheels, advanced profiling software, and five rugged carrying cases for safe transport and field use. Wireless data acquisition and intuitive software streamline setup, measurement, and reporting, reducing inspection time while improving measurement consistency.

By enabling condition-based maintenance, the RollProf roll profiling system helps eliminate unnecessary roll changes, minimize unplanned downtime, and significantly reduce maintenance costs. Rolls are replaced only when wear data confirms it is necessary—maximizing asset life and improving operational efficiency.

Ideal for predictive maintenance programs, the RollProf 3T 1000-1600-100P is the professional solution for accurate roll measurement, cost control, and improved reliability in paper mills, steel plants, and other roll-intensive industries.