The RollProf 3T 100–1600P Complete Roll Profiling System is a high-precision solution designed for accurate measurement of roll profiles and roll lengths directly in demanding production environments. Engineered in collaboration with maintenance experts from the global paper and steel industries, RollProf delivers reliable, repeatable data that supports condition-based maintenance and reduces unnecessary roll changes.

This comprehensive system supports roll diameters from 260 to 1600 mm and includes the 800 rig with accessories, 1600 rig with accessories, and the PM 1000 rig for in-situ measurements (400–1000 mm). With an exceptional measurement resolution of 0.0001 mm, RollProf enables early detection of wear, deformation, and profile deviations that can impact product quality and machine performance.

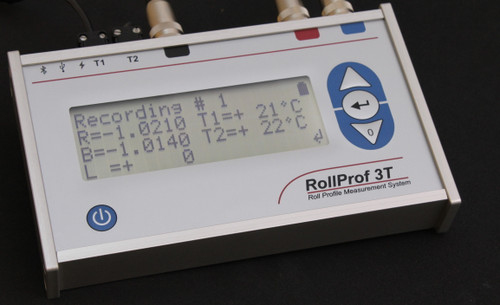

The RollProf 3T 100–1600P is designed for ease of use, robustness, and accuracy. The included Bluetooth data logger, dual pulse wheels, advanced analysis software, and four rugged carrying cases ensure efficient field deployment and seamless data collection. By enabling maintenance teams to replace rolls only when their actual condition requires it, RollProf helps significantly reduce downtime, extend roll life, and lower overall maintenance costs.

Ideal for predictive maintenance and quality assurance programs, the RollProf 3T 100–1600P delivers actionable insights that improve reliability, optimize production, and protect critical assets across paper, steel, and heavy industrial operations.